Oil and Gas

Oil and Gas: 3D Printing’s New Frontier

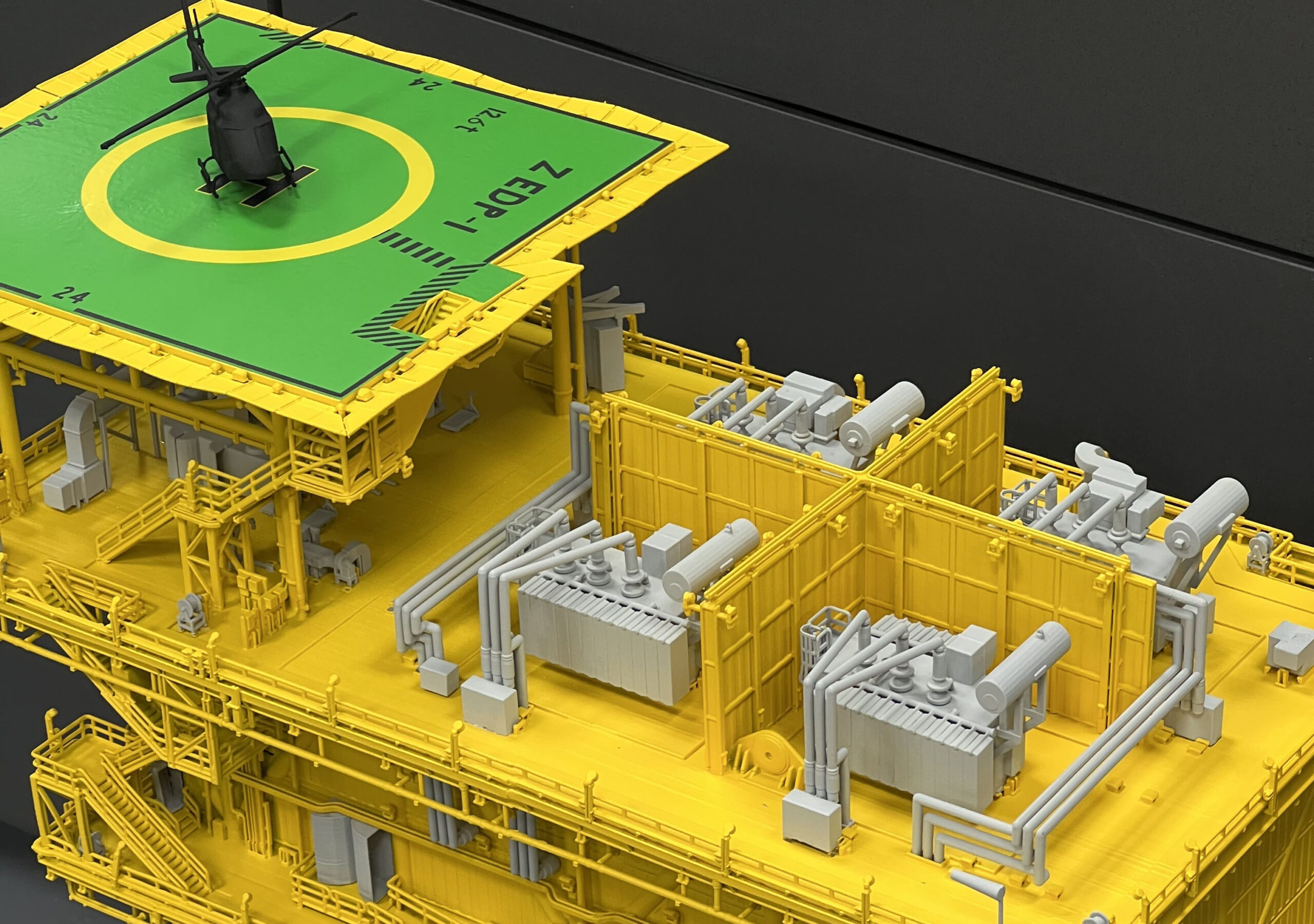

Over the years, 3D printing has emerged as one of the key enabling technologies in driving industrial productivity around the globe. Because 3D printing can create custom, complex parts faster than traditional manufacturing processes, engineers and product developers have found 3D printing to be an ideal solution for low-volume parts and a key element in the next generation of energy, oil and gas components. Key applications of additive manufacturing include 3D printing oil and gas spare parts on-site, testing new product designs and simplifying inventory management to save costs.

Oil And Gas Applications

Functional

Prototypes

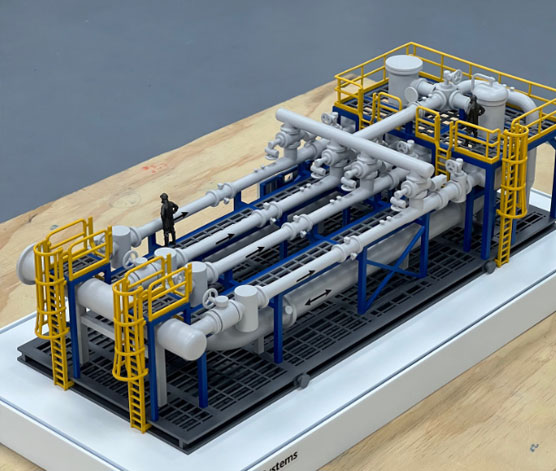

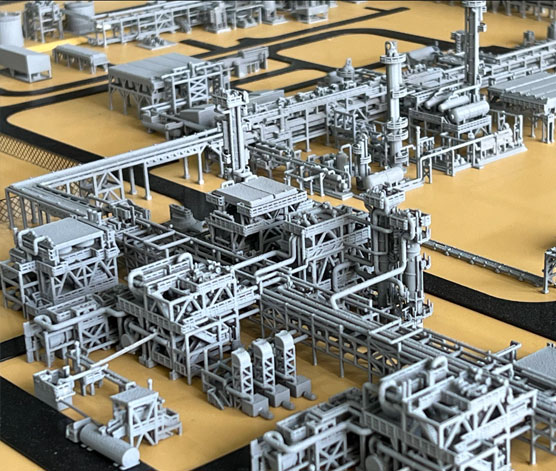

High-Detail

3D Scale Models

Product

Demonstrations

End-Use Parts for Plants & Refineries

Health And Safety

Training Replicas

KEY BENEFITS OF 3D PRINTING IN THE OIL AND GAS SECTOR

Quicker Prototyping Of Parts

One key benefit of 3D printing is the acceleration of product development. 3D printing models allow those in the oil and gas industry to engage in multiple design cycles and quickly test design concepts by reducing the time to proceed with full production.

Produce Complex Geometries

Additive manufacturing is ideal for producing innovative shapes and complex geometries in a short time frame. Compared to traditional manufacturing, additive manufacturing allows for simplified manufacturing of pumps, valves, turbo machinery and other vital components cheaper and faster.

Manufacture Parts On Demand

Oil and gas companies require many low-volume parts that can be immediately manufactured and replaced. 3D printing models for oil and gas applications provided a viable solution to this need. As the industry evolves, the lead time for production needs to be quicker and critical spare parts need to be readily available. Additive manufacturing can reduce warehouse stocks and inventory costs through on-demand manufacturing.